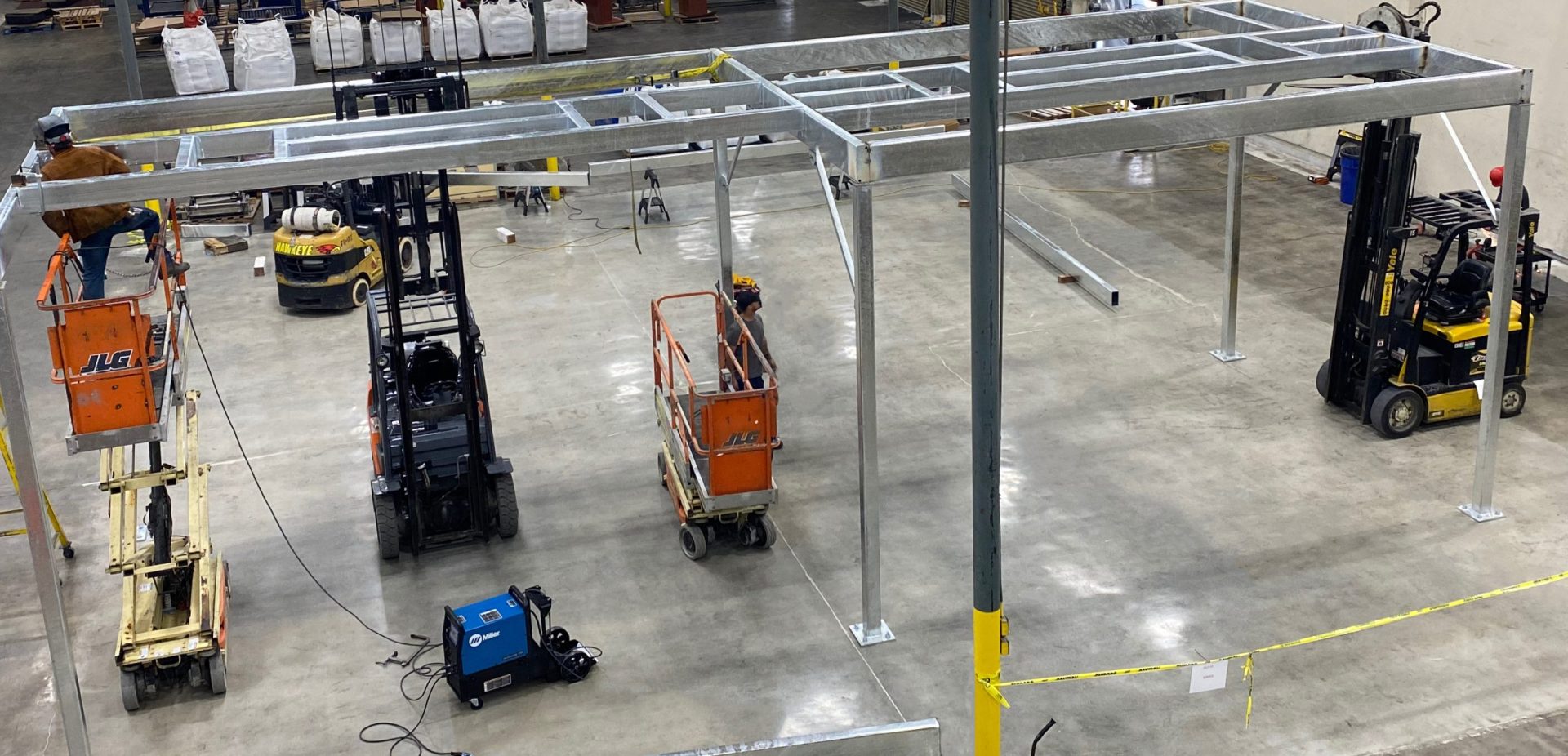

Foss was contracted to fabricate and install an industrial 200 foot mezzanine to support various industrial machines and equipment. This industrial construction build involved the fabrication and installation of 26 baseplates at each column location. A survey crew was brought in to shoot all of the elevations after the baseplates were laid out, enabling prefabrication of everything prior to galvanizing. The project included the prefabrication of baseplates, handrail clips, stair tread clips, end caps for all posts, girts, and handrail posts, and handrail sections. All material handling and aerial equipment was included. The installation phase included setting and anchoring columns, setting girt and joist beams, framing out openings for hoppers, welding out the entire structure, installing handrail sections, and setting diamond plate that was formed offsite with kickplate and pass-through circles already cut. The project was completed in several phases and required extensive pre-fabrication prior to the industrial equipment installation.